|

|

|

|

|

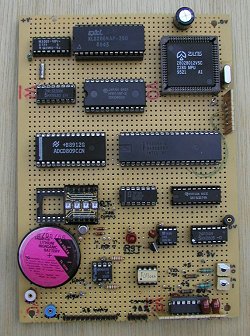

Sadly the Z280 had a relatively short life in production, but one that was meant to help bridge the gap between the Z80 and faster and more complex devices. It was a toss-up in the end which processor I was going to use for this project so the size limitations and the features I needed eventually settled things. For my project I was going to need a UART and, to make life easier in some areas, a counter / timer. Z280 has both of these built in, plus many other facilities I would not be using on this occasion. |

|

|

|

|

|

|

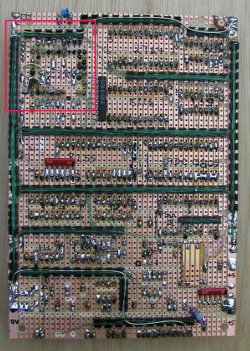

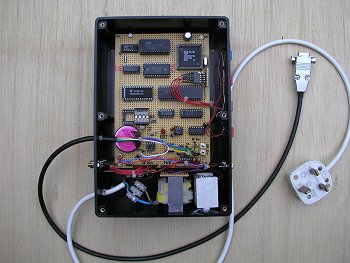

The underside of the finished board showing how I ran out of room - so much so that I had to put the MAX232 RS232 converter chip out on a piggy-back board on the top! The red square doesn’t even start to show how tight things are when wiring up the 68 way socket for the Z280. I found it strange that even with all those pins the thing still had a multiplexed Address and Data bus! For those observant enough to spot the bit of vero-board stuck near the bottom right hand corner, this was covering the RTC lithium battery pins to ensure that nothing shorted them whilst the board was in it’s development stage. Once the design had been checked and was working fine, I substituted HC chips where I could and the complete circuit (including DL1414 display) now uses a fraction over 100mA which I thought was quite acceptable. Two more noteable points were: a) The ‘Watchdog’. In the interests of keeping the controller on-track, regardless of power cuts and glitches, I built a Watchdog reset circuit using a 555 timer with a 1 second cycle. For those not familiar with the concept, a circuit such as this has a 555 connected directly to the RESET line of the processor. If the processor crashes for any reason, the 555 completes it’s cycle and the RESET line is toggled. |

|

|

|

|

|

|

In order to stop the processor being reset every second, the program has to incorporate regular ‘refreshes’ that access the timer (in my case via a line from the 8255) which shorts the timing cap to ground and thus delays the ‘reset’ happening for another second. (ad-infinitum) b) I used some of the non-volatile RAM in the RTC chip to store the status information on which relays are in operation at any time, thus creating a ‘recovery’ situation in the event of a complete power failure. Quite impressive to watch when working properly (I know - as it should!) one can pull the power plug from the wall, hear all the relays drop out, then shove it back in again a few seconds later and everything carries on as it did before the interruption. |

|

|